Ever wondered what kind of considerations and work goes into developing a new piece of hardware? Then take a look at this technical article on how we made our new product, Airtame 2

How we made Airtame 2

The road to a new hardware product is long, arduous and paved with worries. Nevertheless, it’s an exciting process for everyone involved and something you shouldn’t take lightly. Our CEO and Co-Founder Jonas describes it very well here.

Deciding on what a new product should look like and be capable of is challenging to say the least. The new product specifications need to support the entire company strategy, which requires a lot of alignment and maturity within a company.

The specs should also be somewhat future-proof to accommodate for market variations because of the relatively long development time of most hardware products. Many things can go wrong, but in the end, that’s also what makes it so exhilarating.

Now that we have a second generation product out, we thought we’d share with you what the journey towards a new product looks like.

Better, faster, stronger

Our primary objective with the first Airtame was to get rid of cables. It’s a common problem that’s easy to solve with a tool like our first generation product. However, with the feedback we’ve received since, we realized there’s a huge potential to do more than make connection to screens cable-free.

We want to create a more inspiring environment for learning and sharing. To make screens in a professional setting easier to use and more functional for everyone. That’s why we’ve shifted our focus a little bit with the development of Airtame 2. We not only want to kiss cables goodbye; we also want people to use screens better.

It’s been approximately four years and 100,000+ devices shipped since our first device saw the light of day. What happens naturally in the lifetime of a hardware and electronics product is that some components reach their end-of-sales (EOS), which means it’s time to develop a new solution.

There are so many small electronic components that go into making a single device, each produced by different manufacturers spread across the world. The decision to stop or start production of any of these components is taken by their manufacturer based on profitability, supply and demand, and is not something controlled by end-product developers.

It is, however, standard within the industry to announce when parts are being introduced or removed so that development companies can adjust their product pipelines accordingly. This happened with some of the first-gen Airtame components, which, as a stroke of luck, coincided very well with our plans for the next generation product.

While the first Airtame is still a very capable streaming device, things have also started to shift during the four years since its first release, and our users are now hoping to do more with their screens than just screen mirroring. They want to utilize them in ways they haven’t before, such as implementing personalized digital signage, and we want to empower them to do so with Airtame 2.

These are the features our users have been requesting most frequently, and consequently the ones we have sought to improve with Airtame 2:

- More reliable streaming performance, especially when playing videos

- Better support for web content, digital signage, and dashboards

- Faster upgrade times, and improved speed all-round

- Stronger, more reliable wireless connection

- Robust security measures against theft

- Flexible hardware setup and installation

Let’s take a look inside Airtame 2 and check out some of the powerful components we’ve included and how they add value to our users.

Electronic components

When setting specifications and speaking with field application engineers (FAEs) and distributors about what components on the market were suitable for use in Airtame 2, we took complete advantage of the opportunity to select parts that improve on the exact features that our users were requesting. That’s why upgrading the following components was of utmost importance:

Cypress CYW88342 RSDB WiFi chip

Our new RSDB (Real Simultaneous Dual Band – more on this functionality in another article) WiFi chip on the Airtame 2 has more bandwidth than on our first generation, which means that it provides much faster and more reliable internet connection. It’s more than 5 times faster, actually.

With the first-gen Airtame, we received feedback from users that the network speed was relatively slow and you could only reliably stream offline content. We wanted to change that. With Airtame 2, the user can stream internet content such as cloud documents or YouTube videos while using WiFi Forwarding.

We worked closely with the chip manufacturer Cypress and our hardware partner RTX to implement this dual-band chip in an onboard design with custom antennas to maximize performance in all product orientations.

The RSDB functionality of the Cypress WiFi chip makes our product complete.

Ros, Firmware Team Lead @ Airtame

i.MX6 Dual(Core)Plus Processor

The name is quite a mouthful, so let me explain a little bit. Our new processor/SoC (System on Chip) has a better GPU (Graphics Processing Unit) and is much faster, stable, and optimized for graphics. In layman’s terms, that means bigger and more advanced dashboards and websites can be shown. Another nice perk is that when streaming, it can run up to 60 fps while the first-gen Airtame could only go as far as 30 fps.

2GB DDR3L RAM

The Random-Access Memory (RAM) is required for the device to operate. It allows for reading and manipulating data faster than from local storage (eMMC). With Airtame 2, we’ve upgraded both the size and the performance.

Going with a 64-bit data bus means that Airtame 2 can handle twice as much data as its predecessor within the same unit of time. We also increased the size of the RAM from 0.5GB to 2GB, which makes Airtame 2 a much more capable device when dealing with more memory-heavy tasks such as digital signage, dashboards, and apps. Gone are the days where the page would run out of memory!

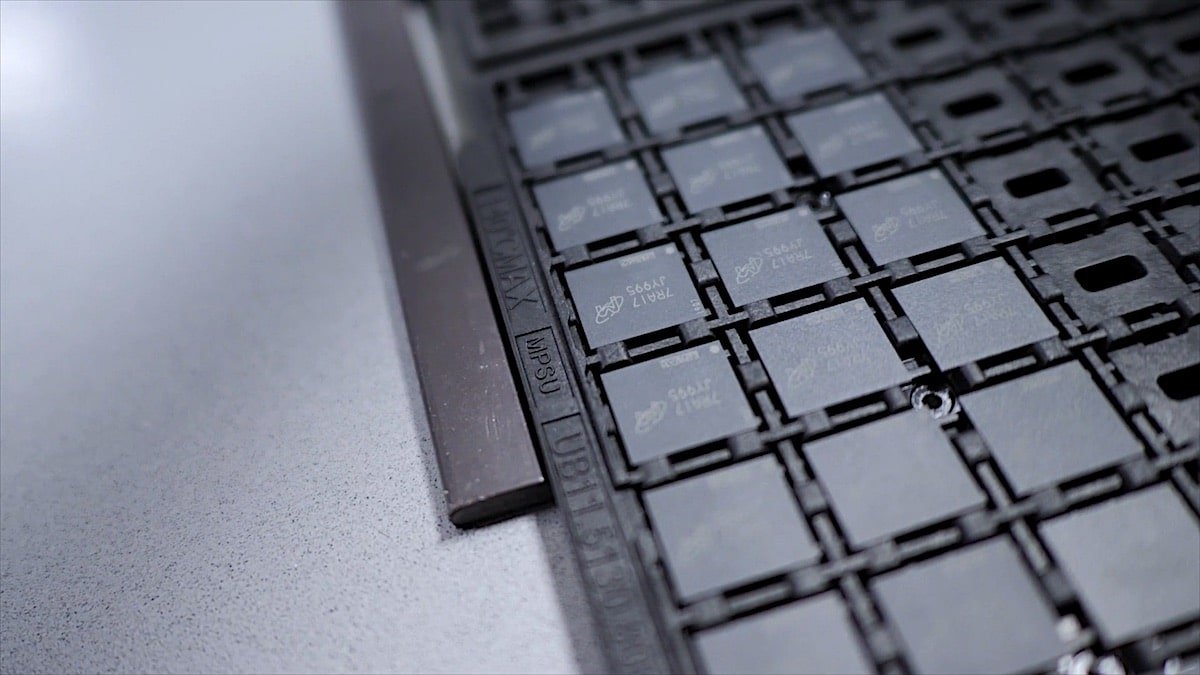

eMMC Storage

We’ve opted to use an eMMC (embedded Multi-Media Controller) instead of a Micro-SD card. The reason we went with this was to save space on the PCB, and to be able to have a more performant, high-speed storage available to hold the Airtame OS. The impact of the speed upgrade can be seen in a reduced boot-up time, and a massive ten-fold speedup for firmware upgrades, going from around 20 minutes for Airtame 1 to between 2-8 minutes for Airtame 2.

Form factor

Unlike its predecessor, the Airtame 2 is designed to be seen. We aimed for an iconic aesthetic that is easily recognizable so that anyone walking into a meeting room, for instance, will recognize Airtame 2 and know that if they need to share their screen, then they can see the device to aid them to do so.

To drive home that point, we wanted to design a device that didn’t look too ‘techy’ or make our users feel alienated by thinking that the device is too big a handful to operate – when in fact the opposite holds true.

I like to call it ‘friendly’ design, and here’s why. There’s an LED light guide on the front that glows with a dimmed, solid white as a standard setting to tell the user that the device is doing just fine. It’s not intrusive, and once again it’s not taking the focus away from the screen. When it’s performing an update, it’s flashing. That way, the LED serves as a way to communicate what the device is doing in an intuitive way that doesn’t require one to read or memorize a manual.

Your Airtame 2 should be your friendly little helper, guiding your way but never being in the way. The new design doesn’t scream tech; instead, it looks intuitive without taking the focus away from what’s important; the screen.

Production and Quality Control

Two words associated with this Airtame 2 production process: patience and integrity. We need trusted suppliers and manufacturers of components to quality check our custom parts and components over anything. Our suppliers are like an extension of ourselves, and we need to treat them with patience and integrity – just like they will treat our product. We work closely with them to implement incoming and outgoing quality checks at each link in our supply chain to ensure that the end product that ends up in the hand of our users is flawless.

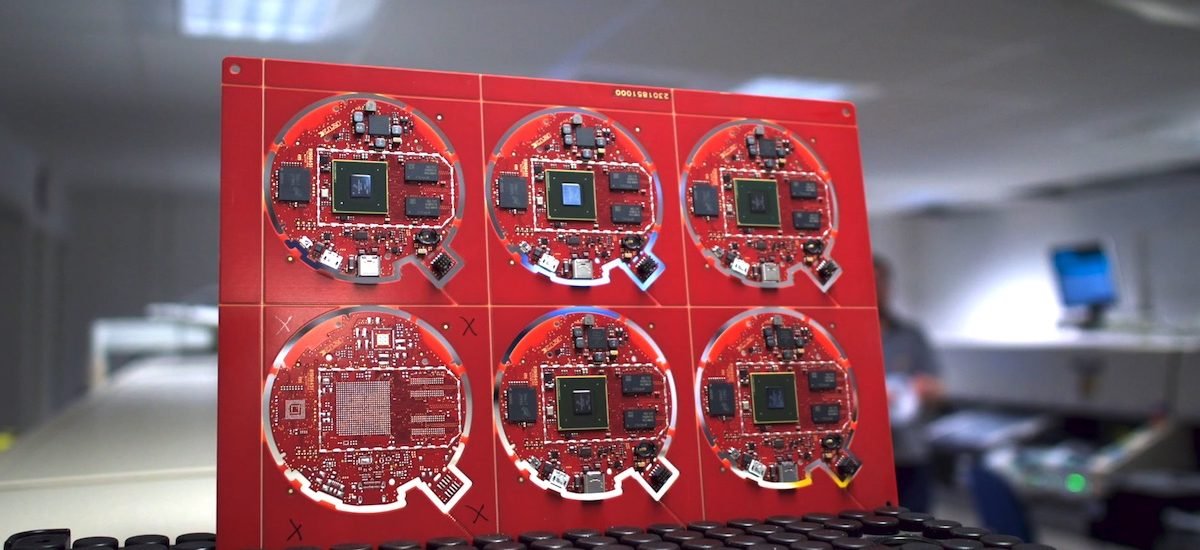

Many of the mechanical parts of Airtame 2 are manufactured in China, Poland, Sweden and Denmark, but the PCB (Printed Circuit Board) is mounted and our final product is assembled and packed in Sweden at our EMS (Electronics Manufacturing Service), Scanfil, in Malmö. They mount the components onto the PCB in their SMT (Surface Mount Technology) production lines and complete the programming, test, and assembly.

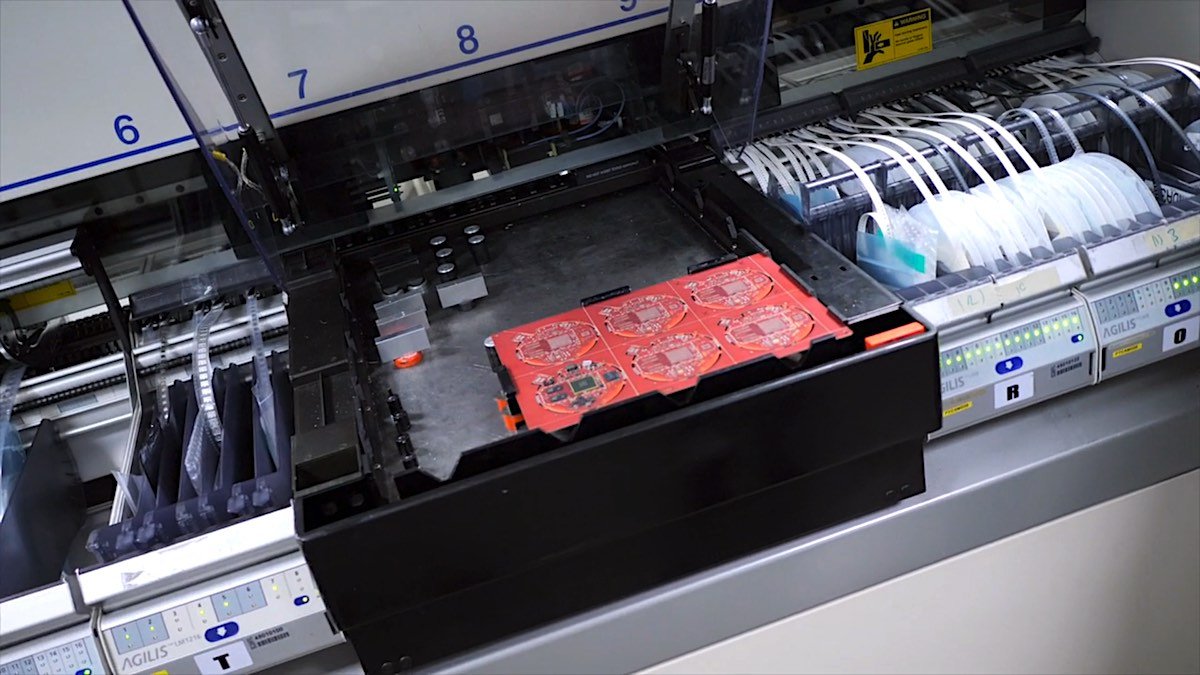

Let’s take a deeper look at what that process looks like. Scanfil receives the PCB panels, each containing four Airtame 2 PCBs. The panels have some exposed copper, which needs to be ‘painted’ with soldering paste using a custom stencil designed for our exact layout before components can be put in position.

Parallel to that, they collect all needed components from their storage system and prepare them to be mounted in the SMT pick-and-place machine by putting the reels or trays of components in special feeders. When the panel (with soldering paste added) finally passes through the production line, the SMT machine has been programmed to place each individual component in the correct location and orientation.

The machine uses visual detection to position the components in exactly the right position, which is crucial as we are dealing with very small tolerances. After the components are placed, the panel continues further down the line through the re-flow oven, where the soldering paste heats up and solders the components, fixing them in place.

Scanfil and Airtame also use AOI (Automated Optical Inspection) along our production line to ensure all components are positioned correctly after re-flow and that no components were missed in the SMT machine.

After SMT and re-flow comes a series of production stations for programming, assembly and testing. The process of starting with the raw PCB and ending with the packaged product is what we call the ‘production flow’ and it has been designed and tweaked to ensure quality and traceability is maintained in every step.

Scanfil helped us optimize the timing and implement the production flow of the Airtame 2, and they have been a fantastic partner because they were easy to communicate with and in such close proximity (our HQ is in Copenhagen, and Scanfil is just a bridge-ride across from us in Malmö) that we could have a lot of hands-on meetings together with the exact team that is doing the final assembly of the product. That also means we were able to get real feedback directly from the ‘end user (in production)’ and improve on the user experience and setup of the production flow.

Solving problems face to face rather than discussing them via email is a lot easier. With a good setup and partnership like this, we have a high awareness of what happens at Scanfil, we can support quickly in case of production issues, and have a more hands-on understanding of our production – with the help of the competent employees there.

Infographic: Check out the full production flow for Airtame 2

Packaging

With Airtame 2, we’ve gone with a packaging design that we call an ‘at-a-glance overview’. When you open the box, you’ll find all the essentials right away. The Airtame 2 itself is neatly encased in foam to keep it in place and on the inside lid of the box is a simple setup guide that’s hard not to notice. In the foam just below the device sits the magnetic wall mount and underneath the foam is a (quick) installation guide and the two other parts needed for installation; the Aircord (our custom cable) and the power supply.

We’ve kept our users in mind when we designed the packaging. First of all, we wanted there to be as little packaging as possible – both for ease of setup but also to minimize the carbon footprint. Secondly, it’s easy to assemble and disassemble the box, and it can also be flat packed for easier recycling.

B2B users, such as ours, don’t require ‘pretty packaging’ as much as B2C users do, and we’re very aware of that. For B2C users, it’s important to have good-looking packaging because they might want to resell or keep it in store (think Nike sneakers or iPhones). What B2B users need is a functional packaging design that’s simple to figure out, neat to look at, and easy to throw out (hopefully, recycle) afterward.

Another initiative we have in the pipeline is ‘bulk-packaging’ which will make it easier for our users to unpack and deploy devices for larger roll-outs and of course dispose of the packaging when they need to.

Most of the packaging material is entirely recyclable, and at some point, we would like to become fully sustainable too. That demands us to take a closer look at the entire supply chain and production process. It’s a work in progress but something that’s very important to us so we’ll be working towards that. The Airtame 2 packaging design is a step in the right direction.

Suppliers/Partners

We have a wide variety of skills at Airtame, but we don’t have all the expert competencies required to run a development project. That’s why we partner up with the best-of-the-best to apply the expert competencies to our projects that we ourselves do not possess. We work with our suppliers to find the best working solution throughout the process, from manufacturing the components, through (sub) assembly, to quality control, testing, packaging, and shipping.

In a development process, your suppliers and partners mean everything. Especially when developing (physical) hardware. Our suppliers have been of great help in the process. When it comes to suppliers, we think it should be a mutually beneficial relationship, and we try to make it so. We want them to be a part of the Airtame family with all the trust and loyalty that entails.

Many of our component and part manufacturers are based in China. Because it’s so far away, it’s imperative to get a good relationship up and running and find out whom to trust. Luckily, we have many trusted suppliers. In such a short article, we don’t have space to name the many, many great suppliers that we have collaborated together with on this project, but we would like to shortly highlight a few of them below.

Goodway Plastics

Goodway Plastics, based in HK/China, is our custom injection molded plastic part manufacturer, who are also doing some of our sub-assembly. Goodway Plastics is a new partner for Airtame, but are easy to communicate with and great at finding a solution when problems arise.

For the collaboration to work, we need to trust in their abilities to control these processes, and they really shine at that. There are many concerns when trying to find a good supplier far away, but Goodway Plastics has put all those to shame. They serve as a shining example of a company that has fantastic communication and service despite the remoteness.

Cypress

We have some special relationships with part manufacturers as well. Take Cypress, who manufactures our WiFi chip (IC CYW88342 802.11ac transceiver with RSDB for the tech-heads out there). This relationship is special because it’s the first time this specific RSDB chip has been used in a consumer device outside of an automotive application. They’ve been extremely accommodating and supportive on this new journey, and we’re so excited to have had this opportunity work with them.

RTX

RTX is our hardware development partner and we have spent many months together building and qualifying both our first generation product and Airtame 2. They are really an example of a partner with expert knowledge in radio devices, and without them, we couldn’t have implemented this new Cypress chip and on-board antennas, that optimize our device performance.

They have collaborated with us to really push the limits of innovation with some new advanced components on Airtame 2 that allow us to, for example, have only one USB-C cable going into our device that can provide three things: power, HDMI, and Ethernet.

EKTOS

Finally, we have worked with the Danish testing lab, EKTOS Testing & Reliability Services (TRS), in the final phases of the project to get our device tested and certified for the market. EKTOS TRS has tested our product according to the relevant European and USA/Canadian standards.

Their accredited test reports can be used as a basis for obtaining the necessary certifications. It’s a crucial step in the development process to get these tests done and reported correctly, so we can back up our claims, that we are a safe, tested and reliable product for our end users.

Read more about our EKTOS collaboration here.

Ready for the future?

We designed Airtame 2 with the future in mind. Users shouldn’t have to throw out their hardware annually or biannually just because it doesn’t live up to the new expectations. That’s why we chose to focus on a future-proof solution that works for how we see our users utilizing their screens in the years to come.

Airtame 2 is designed for more demanding digital signage tasks, more advanced cloud app integrations and of course better and more reliable streaming. Some of those features we don’t even have yet, but we know that Airtame 2 can accommodate them.

Our new hardware device, Airtame 2, helps us get towards that goal we have as a business, while simultaneously allowing our customers to use screen better.

Find out more about Airtame and its new features in this short video: